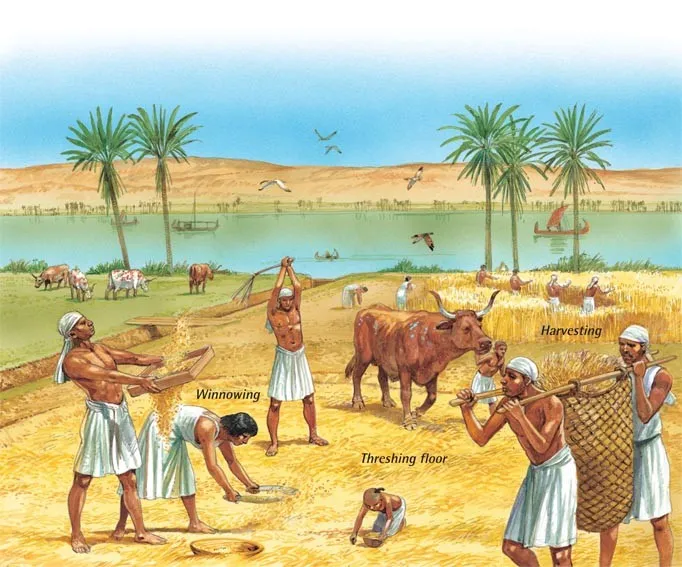

In many farming communities, the real challenge often begins after the crops are harvested. Imagine spending hours, or even days, manually separating grain from husks or stalks. It’s not only exhausting but also leads to significant grain loss. This is a reality for many smallholder farmers, particularly those without access to modern equipment. The solution? Threshing services; an innovative and efficient way to help farmers process their crops quickly and with minimal hassle even as investors make money.

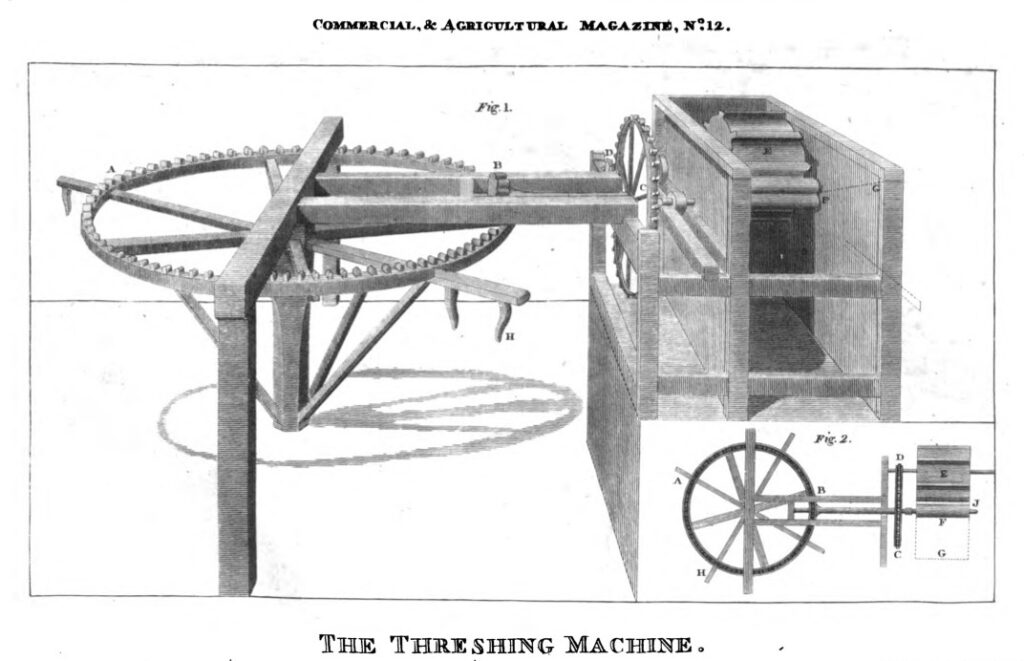

Threshing is the process of separating the edible part of the crop from its inedible husk or stalk, is traditionally done by hand, often with primitive tools. But with the rise of mechanized threshing, a game-changing solution has emerged, which is the multi-crop thresher. But some smallholder farmers cannot afford the thresher. This offers an opportunity for an entrepreneur to offer threshing services to multiple farmers. By providing mechanized threshing on demand, they give farmers faster, cleaner, and more efficient ways to process their harvests.

How Threshing Services Work for Farmers

The concept is simple: an entrepreneur invests in a threshing machine and offers threshing services to local farmers for a fee. The service can be mobile, where the machine is brought directly to the farm, or it can be based at a centralized location where farmers bring their crops to be processed. The beauty of this system is that it eliminates the need for farmers to purchase expensive machinery, and it saves them time and effort during the crucial harvest period.

For the farmers, this service is invaluable. Instead of spending days or even weeks threshing crops by hand, they can get the job done in a matter of hours. The grain is processed more efficiently, with less risk of damage and loss. Plus, by using a mechanized system, farmers can be more productive, freeing up time to focus on other aspects of their farm.

Benefits Threshing Services to Farmers

There are multiple advantages to utilizing threshing services.

- First and foremost, it’s an opportunity for agripreneurs to tap into a growing market. The demand for post-harvest services is high, especially during peak harvest times, and this business model offers a steady stream of income.

- Secondly, it’s a solution to the inefficiencies that many small-scale farmers face. Without access to modern equipment, these farmers often struggle with labor-intensive and time-consuming tasks. By providing a service that makes their lives easier, agripreneurs can help boost productivity and improve the overall quality of harvested crops.

- Lastly, threshing services help reduce food waste. When crops are threshed manually, a significant amount of grain can be lost due to inefficiency or improper handling. A mechanized process, on the other hand, reduces waste, ensuring that farmers get the maximum yield from their harvest.

Finances in Threshing Services: Understanding Costs and Revenue

Now let’s get to the main agenda for this write-up. Before jumping into the business , it’s essential to understand the financials. Starting a threshing service isn’t complicated, but it does require some upfront investment. Here’s a breakdown of the financial aspects you should consider:

Initial Investment

Threshing Machine

The core equipment for starting your threshing service is a multi-crop thresher. A SAYeTECH thresher costs approximately $4,064, with shipping fees of $568. This brings your total capital expenditure (CAPEX) to $4,632.

Transportation & Setup

While a dedicated truck isn’t included in the base costs, operational transport of the machine between farm sites is estimated at $40 per day. You may also need to budget for a small storage space and local registration, though these are often minimal in rural contexts.

Operating Costs

Daily operational costs (OPEX) during the harvest season include:

-

Fuel: $16/day

-

Operator wages: $20/day

-

Transport of machine: $40/day

-

Miscellaneous (repairs, meals, etc.): $15.20/day

That totals to a daily OPEX of $91.20.

For a typical 27 working days per month during a 3-month harvest season, total seasonal OPEX is $7,371.

Revenue Potential

Threshing fees vary by crop, with average rates per hour as follows:

-

Maize: $19/hour

-

Millet: $34/hour

-

Rice: $15/hour

Assuming you thresh maize for 7 hours daily, you would earn:

-

Daily Revenue: $133

-

Monthly Revenue (27 days): $3,591

-

Total for 3-Month Season: $10,773

Profitability

Your first-season financial outlook:

-

Revenue: $10,773

-

Costs (CAPEX + OPEX): $4,632 + $7,371 = $12,003

-

Net Loss (First Season): -$1,230

From the second season onwards, you only incur operational expenses. So:

-

Revenue: $10,773

-

Costs (OPEX + Loss in 1st season): $7,371 + $1,230 = $8,601

-

Net Profit (Second Season): $2,172

With consistent usage, you can expect to recoup your investment and begin generating profit by the second or third harvest season.

Please note: these are just estimates and assume only maize threshing, a farmer hiring the thresher for 7 hours daily, and no downtime.

How to Run a Threshing Service Business

Now you know how how threshing services can be profitable, let’s get to the core of what goes into running such a business. Here’s how to make your threshing business thrive:

1. Choose the Right Location

Success starts with knowing your market. Focus on areas with a high concentration of cereal farmers, especially those growing maize, millet, or rice. These are your primary customers. Not sure where to start? SAYeTECH offers free insights to help you identify the best regions to target. Express interest here.

2. Purchase the Right Equipment

Invest in a reliable and efficient multi-crop thresher like the SAYeTECH ST-6000. It’s built to handle various crops and is easy to transport between farms, giving you the flexibility to serve more clients during the busy harvest season.

3. Build Your Client Base

Farmers are your business. You can start with your own network, but don’t worry if you’re starting from scratch. SAYeTECH provides support to help you connect with farmers, cooperatives, and farmer groups. These partnerships can lead to bulk jobs and recurring clients.

4. Register Your Business

Going legit is good business. Registering your threshing service gives you access to better opportunities, credibility, and long-term stability. It also makes it easier to manage taxes, issue invoices, and keep your books in order. Our team shall assist you with resources to swiftly get your business registration, tax, invoicing, and bookkeeping systems in place! Express interest here.

5. Hire and Train Your Operator(s)

Your operators are the heartbeat of your service. Ideally, hire two trained operators to maximize efficiency and safety. SAYeTECH offers operator training to ensure your staff knows how to get the best out of the machine. The operators will also provide a safe parking spot for your thresher.

6. Stay Informed With Daily Reports

Establish a system of daily and weekly updates from your operators. These should cover machine usage, maintenance, expenses, and cash receipts. This level of reporting ensures accountability and helps you spot issues before they become costly.

7. Leverage Smart Technology (Coming Soon)

SAYeTECH is developing Smart Sensors for real-time data on machine location, usage hours, and more. These tools will help you track operations, prevent misuse, and plan maintenance more efficiently. Get connected on socials to be the first to know when they are released for sale!

Below is a testimonial video of a woman, Afua Helen Ohemeng, who invested in the ST-6000 Multi-crop Thresher and successfully operated a Threshing Service Business that paid off in two harvest seasons!

Conclusion

Threshing services are an innovative way to address the challenges that many smallholder farmers face in post-harvest handling. It offers entrepreneurs an opportunity to build a sustainable business while simultaneously providing much-needed support to local communities. With the right equipment, a solid business plan, and a commitment to serving others, threshing services can be a game-changer for both farmers and agripreneurs.

Is this the right business for you? Get started by expressing interest with us using this form. We design and manufacture the best multi-crop threshers in African and can’t wait to work with you.

Frequently Asked Questions (FAQs)

Do I need to be a farmer to run a threshing services business?

Not at all. This business is perfect for non-farmers who want to work in agriculture. As long as you understand the market, have access to a good thresher, and can manage operations, you’re good to go.

How do I find customers for threshing services?

Start by connecting with farmer groups, agricultural cooperatives, and local extension officers. Word-of-mouth is powerful in farming communities; offering demos or working with just one happy client can lead to more bookings.

What crops can the thresher handle?

The SAYeTECH ST-6000 Gen II can thresh maize, rice, sorghum, millet, soybean, and more. It’s a multi-crop machine, which means you can serve different farmers across different harvests.

Can I start this business part-time?

Yes. Threshing is a seasonal service, so you can easily run it part-time during the harvest season and focus on other work or businesses in the off-season.

What if the machine breaks down during service?

Like any equipment, maintenance is key. Choose a durable model, like SAYeTECH’s ST6000 Gen II, with local servicing options. SAYeTECH provides after-sales-services like prompt-maintenance and mart replacement. Also, train your operator to handle minor repairs. Having a backup plan or small savings buffer helps minimize downtime.

How long does it take to break even?

Typically within two harvest seasons. The first season may not be profitable due to the initial investment, but from season two onwards, your margins increase significantly.

Can I scale the business over time?

Absolutely. As demand grows, you can add more machines, hire additional operators, and cover more villages. Some entrepreneurs even franchise the model or partner with NGOs to expand.