Wikipedia defines a threshing machine or a thresher as a piece of farm equipment that separates grain seed from the stalks and husks. It does so by beating the plant to make the seeds fall out. Before such machines were developed, threshing was done by hand with flails: such hand threshing was very laborious and time-consuming, taking about one-quarter of agricultural labour by the 18th century.

The purpose of this article is to take you on a journey about how threshing evolved, from the use of sticks, to flails, to what we have today.

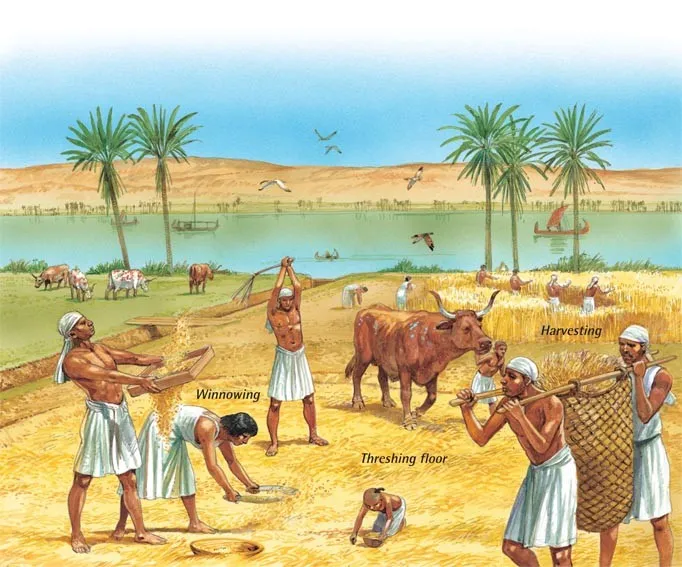

Before the 10th century, long sticks were used as the first tool by Egyptians to thresh grains.

It’s adoption spread to Europe where someone noticed that although banging a stick against the crops separated the wheat from the chaff, connecting one stick to another resulted in greater impact force and little side-effects on the palms that wielded the stick. Voila, the flail was born. It gained widespread use in Europe from the Renaissance through to the 17th century and was adopted in many parts of the world, including Asia.

However, a farmer one day asked, “Could this tool be used against that guy who has been stealing my crops?” And that is how the flail evolved into a weapon and was subsequently embraced by European knights and armies.

In China, it evolved into the “Nunchaku“, a martial arts weapon. I bet Bruce Lee just came to mind.

But we are not talking about weapons today. The threshing machine as we currently know it, can be considered as just a bunch of flails automatically working together.

In the American Cyclopaedia, it’s mentioned that Michael Menzies of Scotland is credited with creating one of the earliest threshing machines, which used water power to drive multiple flails. While not successful, it gained a lot of attention.

In 1758, a farmer named Leckie from Stirlingshire developed a rotary machine with cross arms and a horizontal shaft enclosed in a cylinder. Although efficient for oats, it had issues with wheat. – There are no available visual designs of Menzies’ and Leckie’s model.

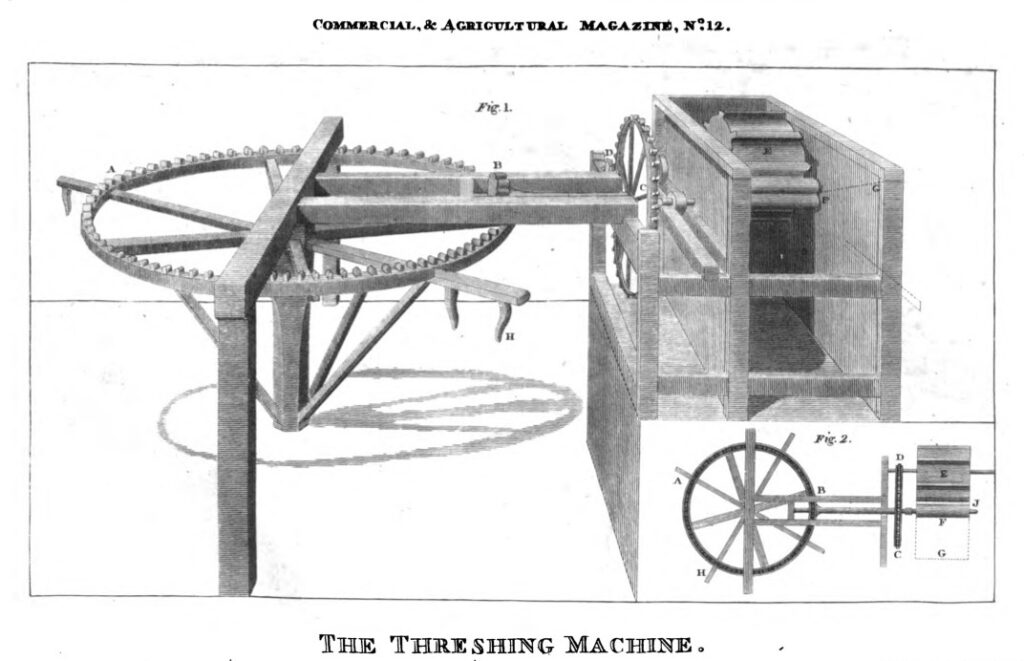

Andrew Meikle later improved upon Leckie’s design in 1786 by adding a drum with beaters and rollers for straw feeding, receiving a patent in 1788 for the first functional machine, which included a fan mill for cleaning grain from straw and chaff. – By this you can guess that Meikle’s design might look a just a little bit like Leckie’s design.

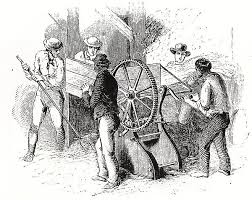

As time passed, other inventors such as “Mr. Pope” (there was no mention of his first name), invented the earliest hand-powered versions of the thresher which were cheaper. The thresher was exhibited by his son Joseph Pope in 1823 in Baltimore, United States.

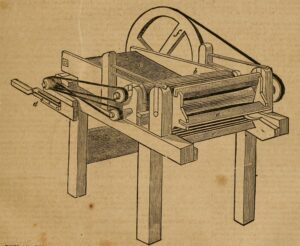

This is an image of other versions of the hand-operated thresher made my Barrett, Exall & Andrews in 1849.

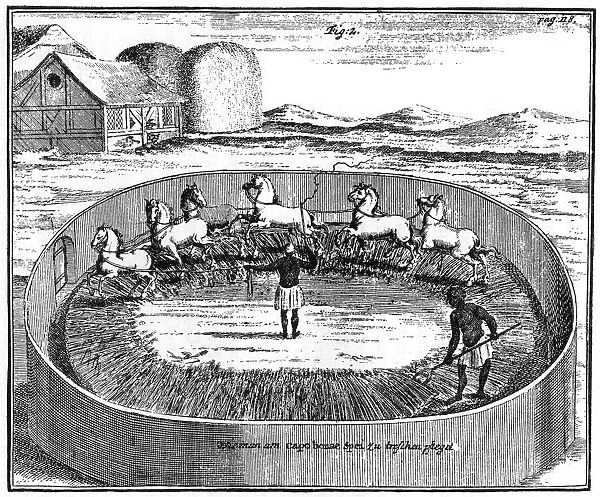

In the 18th to 19th century in Africa, threshing had a rather quite different approach based on tribe. As shown in the picture below, farmers in South Africa made use of horses in a cyclic movement over the crops on a threshing floor to thresh out the grains. This was also common practice across the world during that time.

All the while in Egypt, cattle were used to thread over the grains on a threshing floor, after which the grains are gathered and further winnowed using the wind. The complexity of this process evolved over time from ancient Egypt era (5000 BP) to the 19th century. In one use-case, farmers rather sat on “threshing stool” and were pulled by the cattle. It was called the Noreg wheat threshing machine.

Powered by America’s oil revolution, Americans such as the Pitts Brothers and Cyrus McCormick did a great job by adding steam engines, diesel engine, tractors and more functionality to the mechanical threshing machine. This replaced cattle-powered threshing in the process. At this point, a farmer would love to have one machine that can do the work of a thresher and other machines as well. This led to the invention of the Combine harvester in 1835 in the United States. The first combine harvester, built by Hiram Moore, was capable of reaping, threshing and winnowing cereal grain. However, depending on the size of the farm, we still have various simpler versions of the thresher that are in use today.

Will all this progress in mind, you might think that threshing in the 21st century in most part of Africa would also have advanced. What upsets the founders and all of us at SAYeTECH is that the use of sticks (not even the frail) is still being used by small-holder farmers in Africa.

For reasons such as size of farm, lack of funds or livestock, millions of farmers in Africa endure up to 30% post-harvest losses due to manual threshing. Although most of these farmers mainly farm just to earn little money (which is barely enough) to cater for their families, they aren’t able to scale their farming, because they don’t have the machinery that will allow them to process higher volumes of their harvest. According to World Bank, over $4Billion is lost annually in Africa due to post-harvest losses, meanwhile billions are spent on importation of food. This presents the need for introduction of post-harvest equipment that can assist small-medium sized farms; machines that are smart enough to leverage aggregated farm and yield data to enable these farmers further enhance their output and tap into supply-chain opportunities.

SAYeTECH specializes in the manufacturing of smart post-harvest machinery such as multi-crop threshers, cereal dryers, multi-grain cleaners, cocoa pod breakers and more, all powered by IoT devices for telematics and digital connectivity. This presents a huge turn-around for the agricultural landscape in Africa, when companies such as SAYeTECH are backed to scale these solutions to save millions of farmers billions of profits and better quality of life. This will also lead to a more sustainable and profitable agricultural sector across Africa. With the right partnerships and continuous innovation, we also envision an iot-backed approach to mechanized farming with enhanced functionality, remoting monitoring and limitless opportunities for owners and supply-chain stakeholders.

Join us to make this adventure a success. For any kind of enquiry, reach out to us at admin@sayetech.io.

#YouHaveIt!